About potash Khor and BiyabanakKhur

Potash Complex is the only potash producer in Iran and has the largest potash reserves in the Middle East. This complex is located in the central desert of Iran, 450 km east of the center of Isfahan province and 30 km from Khur biabank city, KPPC Potash complex is now producing more than 50,000 TPY KCl, in addition to 500,000 TPY of NaCl. Our aim is to reach more than 200,000 TPY of KCL and in excess of 1,500,000 tons of NaCl within the next 4 years. For this purpose, that we are heavily investing in the new carnallite ponds together with a new processing plant to reach this goal.

Designer presenters from scratch until now

Dr. Mahmoud Ahmadzadeh Heravi from 1991 to 2003

Mr. Mehran Azimi Engineer from 2003 to October 2005

Dr. Masoud Samiejnejad from October 2005 until the end of that year

Mr. Mansour Shabani from 2006 to 2015

Mr. Ali Alavi Naii from 1394 to 1398

Mr. Omid Reza Mahabali Engineer since 1398 up to now

Potash in the mirror of the media

Introducing Potash Complex Units

Integrated Management System Policy

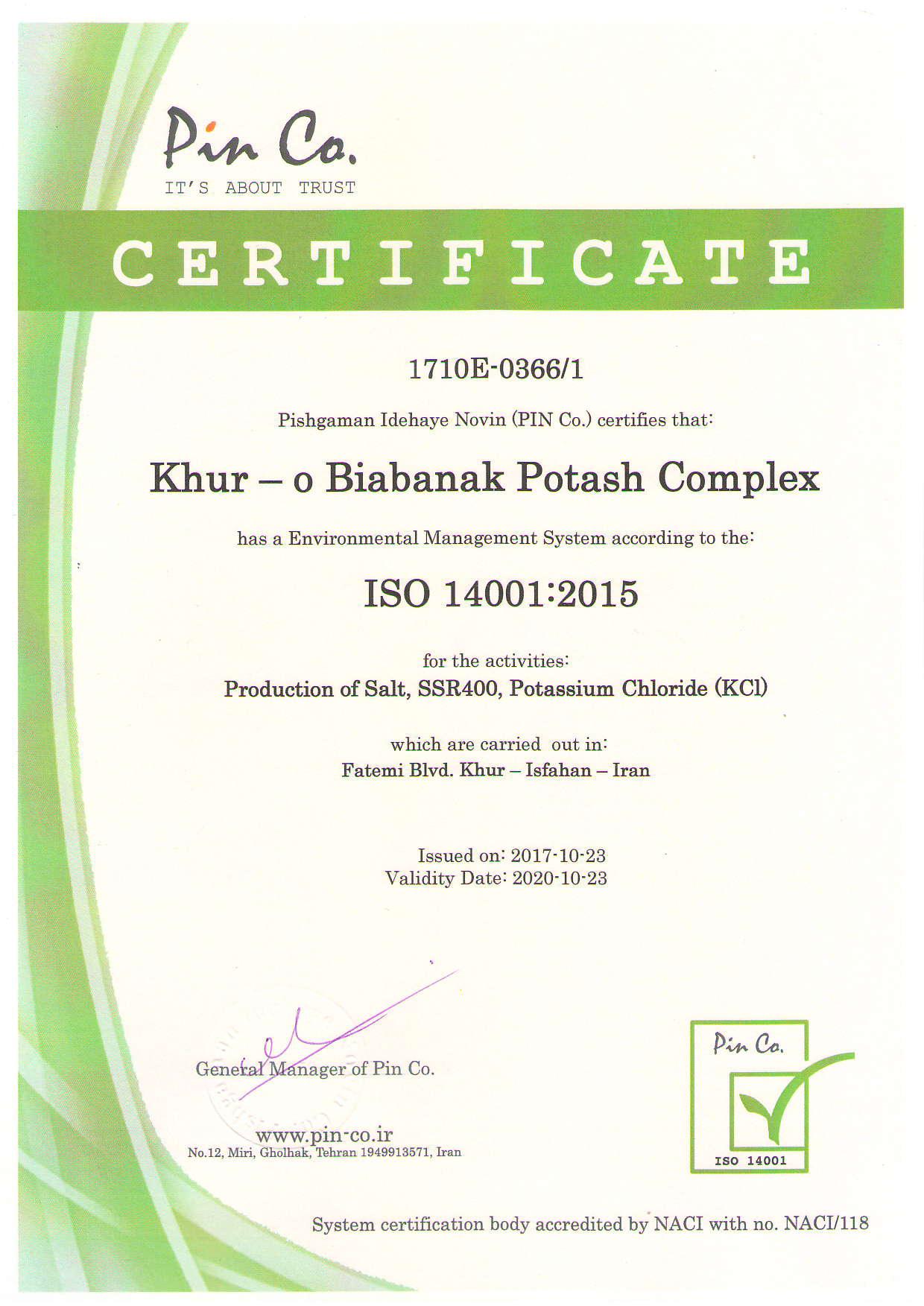

certificates

By developing process-oriented thinking, Potash Khorobiabank Complex has taken a major step towards improving the quality of its product and service, customer satisfaction, improving environmental performance, safety, occupational health and employee health. To this end, it has deployed an integrated management system (IMS) at a complex level and considers itself bound by the following principles:

Continuous improvement in the quality, quantity and product variety of factories (potassium chloride, industrial salt and SSR400 solution)

Increase the satisfaction of employees, customers and stakeholders

Protect the environment and reduce energy consumption

Reduce safety accidents and occupational diseases

Targeted staff training

In order to achieve the above principles, within a year, the complex, in cooperation with Ayvaz Mehr Consulting Company, implemented the Integrated Management System (IMS) at all levels and succeeded

Certifications: ISO 9001: 2015 (Quality Management System), ISO14001: 2015 (Environmental Management System) and OHSAS18001: 2007 (Occupational Safety and Health Management System) Certified by Pin Co.

Requirements of ISO 14001 Global Environmental Management System

ISO 45001 Occupational Health and Safety Management System Standard Requirements

ISO 9001 Quality Management System Standard Requirements

Annual Report – Licenses and ISOs

The importance of the infrastructure needed to implement development projects in a number of key areas can be considered:

Water

Electricity

natural gas

Rail and air transport

Telecommunications and Internet

Capacity (discharge) required for development plans: 1 liter / s

available source:

Emergency 2 MW diesel power plant

1. 2 kW dual circuit network from Khor to Potash site with 2 MW capacity

2. City Capacity: 1 MW

Capacity Required for Future Plans (Public and Private Sector Applicant): 1 MW

Available Solutions for Power Supply Required:

1- Strengthening the city’s capacity by connecting to the 2 kW line

2. Construction of a 2 kW line from Khor to the Potash site

3. Construction of a solar power plant with the participation of the private sector according to the conditions of the region

Available Resources: There are currently no transit lines up to the 2 km radius of the complex. Of course, the CNG (reservoir) gas pipeline project to the urban and rural areas of the city is on the agenda of the National Gas Company, but it certainly will not meet the needs of the city’s industries, especially the Potash Complex. Capacity Requirements for Existing and Development Plans (Public and Private Sector): Over 2 million cubic meters per year Given the importance of discussing the importance of natural gas supply for implementation of development plans, correspondence has been made with the National Gas Company, which we hope to look at. A special honor to the government to build a nationwide gas pipeline to the final and operational city.

Status: Currently there are no railroads up to the 2 km radius of the complex

Road distance to the nearest stations:

1- Tabas Station:160 km

2- Zarrin Station: 182 km

3- Rabat Station: 190 km

Correspondence with the Railway Company of the Islamic Republic of Iran (RAJA) has been pursued in order to assess the feasibility of connecting the Potash Khorobiabank Complex to the national rail network.

Correspondence with the Railway Company of the Islamic Republic of Iran (Raja) has been communicated and the matter is being pursued in order to assess the feasibility of connecting the Potash Khorobiabank Complex to the national rail network.

Status: Currently the entire industrial site and part of the mining site is covered by the mobile network. With the development of the mining sector (Midway and Troode) on the agenda, network coverage across the entire area is considered to be the main strategy and correspondence with the Infrastructure Communications Company has been addressed.